Product Description:

FRP Moulds are an essential component in modern manufacturing processes, particularly in industries requiring precision, durability, and efficiency. Known for their exceptional qualities, FRP moulds serve as a reliable solution for producing high-quality composite parts with consistent results. One of the standout features of these moulds is their lightweight nature. Lightweight FRP tooling significantly reduces handling and transportation difficulties, improving overall production efficiency and worker safety. This characteristic makes them highly desirable in sectors such as aerospace, automotive, and renewable energy, where weight reduction is a critical factor.

In particular, the use of FRP moulds in the production of wind turbine components has revolutionized the renewable energy industry. Wind turbine FRP molds are designed to meet stringent performance and durability standards, ensuring that the manufactured blades and parts can withstand harsh environmental conditions. The lightweight attribute of these moulds not only facilitates easier installation and maintenance but also contributes to faster turnaround times in manufacturing processes, ultimately supporting the growth and scalability of wind energy projects.

Another vital advantage of FRP tooling is its strong chemical resistance. These moulds are engineered to resist degradation from exposure to various chemicals, resins, and solvents commonly used in composite manufacturing. This chemical resistance ensures the longevity and reliability of the moulds, minimizing downtime and maintenance costs. Manufacturers benefit from the consistent performance of FRP moulds, which maintain their integrity and precision even after repeated use with aggressive materials.

The shape of FRP moulds is fully customizable, allowing manufacturers to create complex and intricate designs tailored to specific project requirements. This flexibility enables the production of bespoke components that meet exact specifications, whether for prototyping or large-scale production. Customizable FRP tooling supports innovation by enabling designers to push the boundaries of form and function without compromising on quality or structural integrity.

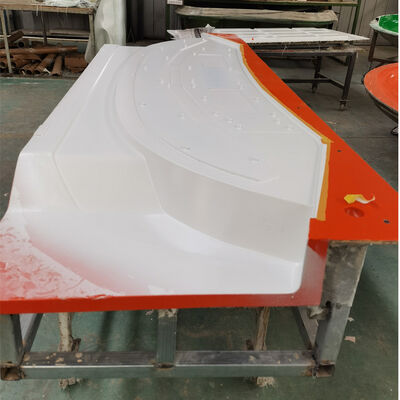

Surface finish is another critical aspect of FRP mould quality. These moulds provide a smooth surface finish that directly translates to the quality of the final product. A smooth mould surface ensures that the composite parts have minimal imperfections, reducing the need for additional finishing work and improving overall aesthetic appeal. This feature is particularly important in industries where surface quality impacts both performance and visual standards, such as automotive body parts and consumer goods.

Moreover, FRP moulds exhibit excellent weather resistance, making them suitable for outdoor and harsh environment applications. Their ability to withstand UV radiation, moisture, temperature fluctuations, and other environmental stressors ensures that the moulds maintain their structural integrity over time. This durability is crucial for wind turbine FRP molds, which must endure prolonged exposure to the elements without compromising performance or safety.

In summary, FRP moulds offer a combination of lightweight construction, strong chemical resistance, customizable shapes, smooth surface finish, and excellent weather resistance. These attributes make them an invaluable asset in various industries, especially in the production of wind turbine components where precision, durability, and efficiency are paramount. Lightweight FRP tooling not only enhances manufacturing processes but also supports sustainable practices by enabling the creation of high-performance, long-lasting composite parts. With their proven benefits, FRP moulds continue to be a preferred choice for manufacturers seeking reliable and versatile tooling solutions.

Features:

- Product Name: FRP Mould

- Surface Finish: Smooth, ideal for sanitary ware composite mold applications

- Shape: Customizable to meet specific design requirements

- Corrosion Resistance: Strong, ensuring long-lasting performance

- Impact Resistance: Strong, providing durability under heavy use

- Colour: White or other optional colors available

- Durable composite mold designed for repeated use and high reliability

- Perfect choice for sanitary ware composite mold manufacturing

Technical Parameters:

| Control |

CNC Machine |

| Shape |

Customizable |

| Colour |

White Or Other Optional |

| Material |

Fiberglass Reinforced Plastic |

| Mold Type |

Customizable |

| Service |

ODM Or OEM (Mold customization service) |

| Lightweight |

Yes |

| Size |

Customizable |

| Weather Resistance |

Excellent |

| Impact Resistance |

Strong |

Applications:

The LANMON FRP mold is a highly versatile and reliable product originating from China, designed to meet the diverse needs of various industries. Renowned for its exceptional lightweight properties, this Lightweight FRP tooling is ideal for applications where ease of handling and transportation are essential. The FRP mold’s customizable color options, including the standard white or other optional colors, allow for tailored solutions that perfectly match specific project requirements, enhancing both functionality and aesthetics.

One of the primary occasions for utilizing the LANMON FRP mold is in the manufacturing and prototyping sectors. The Custom FRP mold can be precisely engineered to create detailed and complex shapes, making it invaluable for producing automotive parts, aerospace components, and consumer products. Its strong chemical resistance ensures durability and longevity even when exposed to harsh chemicals, which is crucial in industrial environments where corrosive substances are common.

Weather resistance is another standout feature of the LANMON FRP mold, making it suitable for outdoor applications such as architectural elements, marine equipment, and infrastructure components. The excellent weather resistance guarantees that the mold maintains structural integrity and performance despite exposure to extreme weather conditions like rain, UV radiation, and temperature fluctuations.

In addition to industrial manufacturing, the Lightweight FRP tooling is widely used in the construction industry for creating molds used in precast concrete elements, decorative panels, and custom-designed fixtures. Its lightweight nature simplifies the installation process and reduces labor costs, while the customizable color options allow architects and designers to achieve visually appealing results that align with their creative vision.

Overall, the LANMON FRP mold stands out as a high-quality, adaptable solution suitable for numerous occasions and scenarios. Whether in automotive prototyping, marine applications, construction projects, or custom manufacturing, this FRP mold offers unmatched chemical and weather resistance, lightweight design, and customizable features that meet the demanding standards of modern industry.

Customization:

LANMON offers exceptional product customization services for FRP Moulds, designed to meet diverse industry needs. Our sanitary ware composite mold solutions are crafted with strong corrosion resistance and impact resistance, ensuring durability and long-lasting performance. We specialize in marine FRP mold production, providing excellent weather resistance to withstand harsh marine environments. Our lightweight FRP tooling is engineered with a smooth surface finish, enhancing efficiency and ease of use in various applications. Whether you require ODM or OEM services, LANMON, originating from China, guarantees high-quality molds tailored to your specifications.

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!